Anatomy of a Control Valve

Introduction

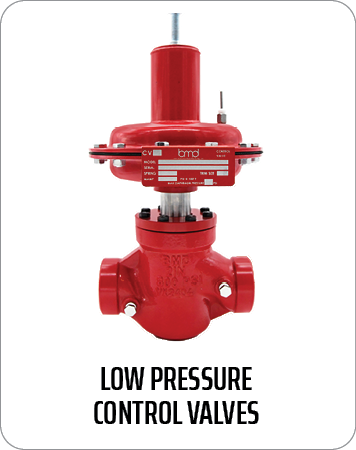

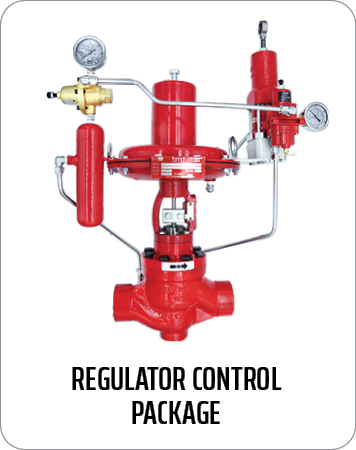

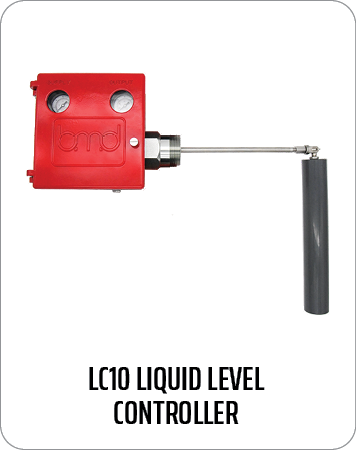

Control Valves play a crucial role in modern oil and gas operations, managing flow, maintaining pressure, and supporting overall process stability. In harsh upstream and midstream environments, the performance and reliability of these valves can significantly impact operational safety, efficiency, and profitability. At Beaumont Manufacturing and Distribution (BMD), we specialize in American-made control valves engineered for the extreme conditions found in oilfields and processing facilities. With decades of industry experience and a commitment to quality, our valves are trusted worldwide for their durability and field-tested performance. In this guide, we’ll explore the anatomy of a BMD control valve, breaking down the core components and highlighting what makes our products stand out in demanding applications.

What Is a Control Valve?

A control valve is a mechanical device that regulates the flow of fluid—such as oil, gas, steam, or water—by varying the size of the flow passage in response to signals from a control system. These valves allow for continuous modulation, unlike isolation valves, which are either fully open or fully closed.

Why Control Valves Matter in Oil and Gas

In the oil and gas sector, precision and reliability are everything. Control valves must:

- Maintain steady volume levels

- Regulate temperature via fluid control

- Ensure consistent flow rates

- Respond quickly to changes in process conditions

- Operate under high-pressure, high-temperature, and corrosive environments

BMD’s valves are engineered specifically for these needs. Whether you’re operating in the Permian Basin or offshore platforms, our valves help you maintain safe, smooth, and optimized processes.

Core Components of a BMD Control Valve

A control valve is more than the sum of its parts—it’s a fully integrated system designed for optimal control and longevity. Here’s a closer look at each component in a BMD valve and the value it brings to the table.

Valve Body

The valve body is the primary pressure-retaining structure and the base of the control valve. It houses internal components and provides the flow path for the process fluid.

BMD Valve Body Features:

- Materials: High-grade cast or forged carbon steel, stainless steel.

- Designs: Globe-style and angle-body configurations to suit different space and flow requirements.

- Compliance: All valve bodies Designed in accordance with ASME and other piping code standards.

Actuator

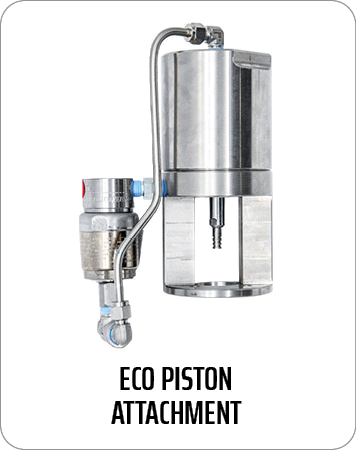

The actuator converts a control signal into mechanical motion, moving the valve plug, disc, or ball to modulate the flow.

BMD Actuator Options:

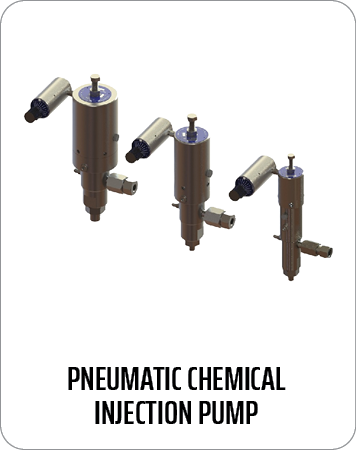

- Pneumatic Actuators: Reliable even in remote locations with limited power sources. Actuators are available as either Reverse Acting (Fail-Closed) or Direct Acting (Fail-Open) to default to a safe position in power loss situations.

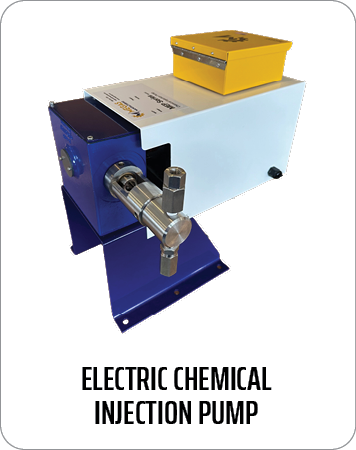

- Electric Actuator: An emissions-free device.

Trim Assembly

The trim refers to the internal elements directly responsible for flow control, including the plug, seat, and stem. These components determine the valve’s flow characteristic and shut off performance.

BMD Trim Advantages:

- Material Selection: Hardened stainless steel, tungsten carbide, D2 tool steel and other specialty coatings to resist wear and galling.

- Flow Characteristics: Linear, equal percentage, or quick-open profiles.

- Noise and Cavitation Control: Anti-cavitation trim designs available for high ΔP (differential pressure) applications. We do not offer any anti-noise or anti-cav trim.

- Metal to metal seating: BMD offers metal to metal seating in our larger full port valves for extended life in erosive service.

- Unbalanced large valve trim: Our offering of unbalanced trim is great for sandy service so that sand doesn’t pack behind the valve plug like on a balanced valve.

Our trim extends service life in abrasive media applications like sand-laden crude or produced water. Each trim set is precision-engineered and pressure-tested for tight shutoff and responsive modulation.

Bonnet

The bonnet serves as a pressure boundary and provides a guide for the stem while supporting the packing system.

BMD Bonnet Design Features:

- Bolted or Pressure-Sealed not sure what ‘pressure sealed’ means. The design of the bonnet will vary by valve series but there are no options within a particular valve series.: Available depending on the pressure class and maintenance preference.

- Materials: Compatible with body materials to meet the same pressure, temperature and service as the body.

BMD’s bonnet assemblies are designed with easy maintenance in mind, and can be removed to service the valve without taking the valve body out of line.

Packing and Sealing System

The packing system prevents leakage along the valve stem by creating a seal between internal and external environments.

BMD Sealing Solutions:

- All BMD control valves come with BMD’s patent pending low-emissions packing system.

- Packing Materials: Engineering PTFE and rubber packing set.

- Environmental Compliance: Certified to ISO 15848

- Live-Loaded Packing: No external packing adjustment is needed. Excellent performance in high cycle applications.

Integrated Performance: Engineered as a Complete System

At BMD, we don’t just build valves—we engineer systems. Each valve is a culmination of component synergy, where design tolerances and material compatibility are fine-tuned to deliver peak performance.

Performance Testing

Before a valve leaves our Beaumont facility, it undergoes a battery of performance tests, including:

- Hydrostatic Pressure Testing (per API 598)

- Leakage Testing (ANSI/FCI 70-2 Class IV–VI)

- Actuator Stroke and Response Verification

This comprehensive quality control ensures that BMD control valves deliver predictable, reliable service in any condition, from high-pressure gas transmission to corrosive chemical injection.

Common Applications of BMD Control Valves

Our valves are field-proven in critical systems, including:

- Oil Production Units – separators, heater treaters, and flowlines

- Gas Processing – dehydration units, compressors, and scrubbers

- Midstream Pipelines – pressure regulation and pigging stations

- Water Injection and Disposal – high-pressure, high-volume service

Each application demands specific capabilities—from pressure rating to media compatibility—which is why we offer a wide range of valve configurations and customizations.

What Sets BMD Control Valves Apart?

When choosing a control valve manufacturer, it’s not just about specs—it’s about partnership. Here’s why oil and gas operators trust BMD:

- Made in the U.S.A. - All our control valves are manufactured in the United States, with full traceability and quality assurance. This not only supports American jobs but ensures faster lead times and easier compliance with domestic sourcing requirements.

- Short Lead Times - Thanks to in-house manufacturing and a streamlined supply chain, BMD delivers where others delay. For mission-critical projects, our fast turnaround times reduce costly downtime.

- Unmatched Customer Support - We don’t just sell valves—we support systems. Our engineers work directly with your field teams to select, troubleshoot, and maintain your valve assets for long-term performance.

- Reduce Emissions with BMD’s Super Red packing - BMD’s patent pending Super Red packing system is standard in all BMD’s control valve lines. This proprietary material blend has been tested to ISO 15848 and will help ensure site OOOO compliance.

Conclusion: Precision You Can Trust

Understanding the components and functions of a control valve is essential for engineers and operators tasked with optimizing performance and reducing risk in oil and gas systems. With Beaumont Manufacturing and Distribution, you’re not just buying a valve—you’re investing in a product designed to perform where it matters most.

Each BMD valve reflects our commitment to rugged design, material excellence, and technical support. Whether you’re retrofitting an existing system or building a new facility, we’re ready to help you select the ideal control solution.

Need Expert Help?

Let BMD support your operation with precision-engineered solutions and real-world experience. Contact our team today for expert technical guidance or to request a quote tailored to your application.