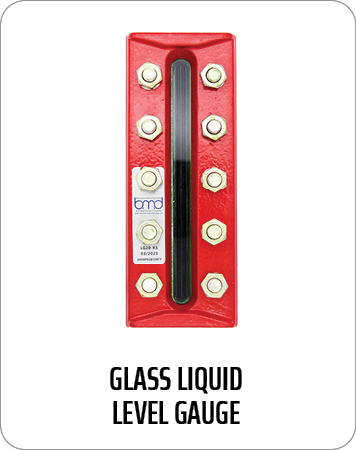

LG20

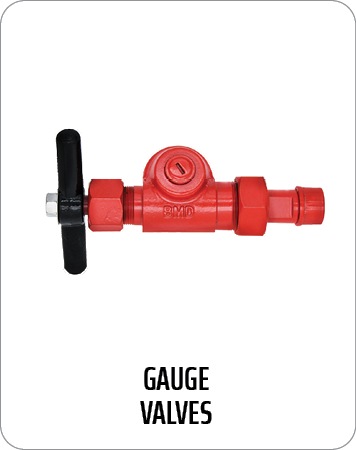

Gauge Valve

The GV20 gauge valves offer ease of installation and compatible with all armored flat-glass level gauges

Power Features:

- LG20 glass liquid level gauges are rugged flat glass gauges

- Expertly made for mid-range pressure temperature applications

- Standard construction includes a solid one-piece chamber machined from carbon steel with covers, toughened glass and chrome-molybdenum bolts and nuts

- All metal parts are rustproofed

- Recessed gasket seat prevents movement and insures leak-free service

| Specifications | ||

|---|---|---|

| Connections: | 1/2” FNPT top-bottom connections | |

| Pressure/Temperature Ratings: | Varies by glass size and style | |

| Gauge Style: | Reflex | Transparent |

| Glass Sizes: | 3-9 |

| Materials | |

|---|---|

| Liquid Chamber: | Carbon Steel |

| Cover: | Carbon Steel |

| Bolts and Nuts: | Plated Carbon Steel |

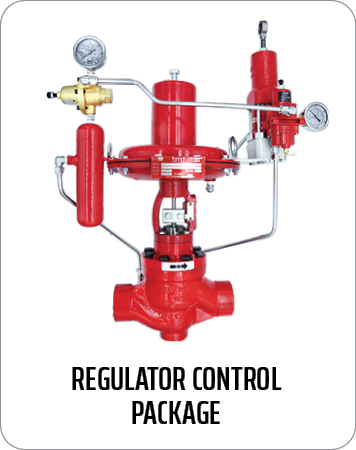

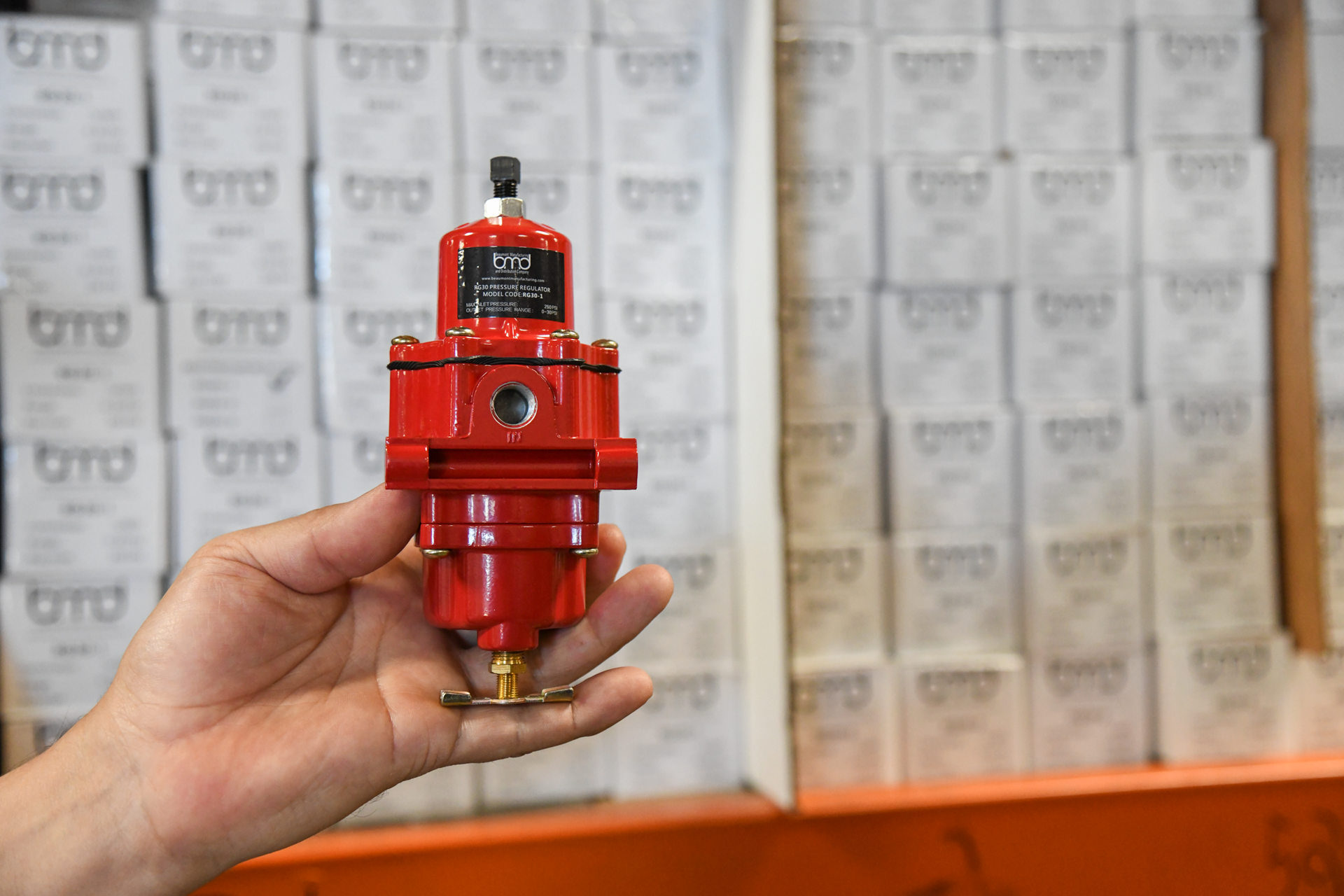

Check out BMD's Pressure Regulator Package

Contact sales to start your purchase for your next project

Related Articles & Training

April 29, 2025

The Basics of Pressure Regulators: What They Are and Why They Matter Oil and gas production systems are characterized by unsteady dynamics due to multiphase, turbulent flows. Sudden gas pressure surges can rupture pipelines and equipment, potentially triggering catastrophic fires or explosions. That’s why precise and reliable pressure control is critically important for oil and gas production systems. Pressure regulators are self-contained, spring-loaded valves designed to control system pressure, either before or after the regulator. Their self-powered operation makes them an efficient and cost-effective solution for pressure management. Unlike control valves, regulators function without the need for external power sources like air pressure or electric actuators, simplifying installation and reducing operational costs. For large Oil and operators, who process fluids from hundreds of wells, the cost of pressure control valves is an important consideration. Pressure regulators, due to their simple self-contained design, are a cheaper option to conventional actuated control valves. However, when pressure or flow ranges exceed a regulator’s capacity, control valves or pilot-operated pressure-reducing valves will become necessary. At Beaumont Manufacturing and Distribution Company (BMD), we excel in industrial pressure regulator and control valve technologies, coupled with a profound understanding of the unique pressure control demands of the oil and gas sector. From our manufacturing facilities in Texas, we deliver a diverse range of pressure-reducing regulators, back pressure regulators, and specialty models. Designed with a focus on durability, safety, and efficiency, BMD pressure regulators are engineered to perform reliably in th e most challenging production environments. What Is a Pressure Regulator? A pressure regulator is a self-contained pressure control device, designed to maintain the specified pressure level within a system. It can perform either a pressure reducing function or a backpressure control function. Pressure Reducing Regulator s lower upstream pressure to a consistent downstream pressure, regardless of variations in upstream pressure. Conversely, Back Pressure Regulator s ensure that upstream pressure remains steady, regardless of changes in downstream pressure. Regulators operate through three key mechanically interconnected elements. The first is a control element, consisting of a movable disc and a seat which adjusts process fluid flow by varying the flow area in the valve by moving the disc closer or further from the seat. The loading element, often a spring, sets the pressure. The sensing element, typically a diaphragm, balances force and adjusts the discs position from the seat, maintaining consistent system pressure despite condition changes.

March 18, 2025

When it comes to maintaining efficiency and safety in oil and gas operations, selecting the right regulator for your system is paramount. Regulators play a critical role in controlling pressure and ensuring consistent system performance. For field maintenance supervisors, field operators, and engineers, understanding the factors that influence regulator selection can mean the difference between optimal performance and costly downtime. To help you make an informed decision, here are five key factors to consider when choosing the right regulator for your system: 1. Inlet and Outlet Pressure Requirements One of the most important considerations when selecting a regulator is understanding the system’s pressure requirements. The regulator must be able to manage the outlet (downstream) pressure within the desired range. Inlet Pressure: This is the pressure coming into the regulator from the upstream side. Ensure the regulator is rated to handle the highest potential inlet pressure to avoid damage or failure. Outlet Pressure: This is the controlled pressure the regulator delivers downstream. Look for a regulator that provides precise control to match the specific requirements of your equipment or process. Most regulators have one or more pressure ranges they can be adjusted to. Maximum Allowable Working Pressure (MAWP) : Ensure the regulator can handle peak flow demands without causing pressure instability. Mismatched pressure ratings pose a significant risk, potentially causing pressure drops, inconsistent performance, or equipment damage. When selecting a regulator, it’s crucial to consider both the maximum pressure it can handle on the upstream side and the maximum pressure drop it can withstand—defined as the difference between the inlet and outlet pressures. Additionally, the regulator’s shutoff pressure, which is the maximum pressure it can manage when closed, must also be taken into account. 2. Flow Rate Specifications Flow rate refers to the volume of media (gas or liquid) that passes through the regulator over a given time. Regulators are designed to accommodate specific flow ranges, so understanding your system’s flow demands is crucial when selecting the right regulator. To ensure consistent performance, it’s important to choose a regulator with the correct orifice size for the required flow rate and pressure drop. Selecting the appropriate size helps maintain stable pressure and prevents excessive wear and tear on the system. Also, consider how variations in flow rate may affect downstream equipment to avoid performance issues. 3. Compatibility with System Media The media passing through the regulator—whether gas, liquid, or a combination of both—can significantly impact its performance and longevity. Regulators are constructed with various materials to ensure compatibility with specific media. Corrosion Resistance: Ensure the regulator’s internal components are made from materials that resist corrosion from the specific gases or liquids in your system. For example, stainless steel or specialized coatings may be required for highly corrosive media. Seal Materials: Elastomer seals and diaphragms must also be compatible with the media to prevent degradation. Certain materials, such as Viton or Buna, may be better suited for specific applications. Choosing a regulator designed for your specific media not only enhances safety but also increases the regulator’s lifespan by reducing wear and ensuring optimal performance. 4. Operating Temperature Range In oil and gas applications, systems often operate under extreme temperature conditions. A regulator’s performance can be compromised if it’s not designed to handle the temperature range of your application. High-Temperature Environments: Regulators used in hot environments must have components capable of withstanding heat without losing integrity. Low-Temperature Environments: In colder conditions, materials like seals and lubricants must resist freezing or becoming brittle. Always check the manufacturer’s temperature ratings for the regulator and ensure they align with your system’s operational environment. Also consider environmental conditions in outdoor installations or in regions with extreme climates. 5. Environmental and Installation Considerations Beyond the operational parameters, the environment and installation and setup play a vital role in regulator selection. Consider the following: Environmental Factors: Will the regulator be exposed to corrosive atmospheres, saltwater, or humidity? If so, choose a regulator with an appropriate protective coating or material. Space Constraints: Ensure the regulator’s size and orientation fit within the available installation space. Compact designs may be necessary in tight spaces. Maintenance Accessibility: Regulators require regular maintenance to ensure optimal performance. Choose a model that allows for easy access to components like diaphragms, seals, and filters. Additionally, consider the system’s operational demands, such as vibration or pulsation, and select a regulator designed to withstand such conditions. Additional Consideration: Future Scalability Oil and gas systems often evolve to accommodate higher production volumes or different operating conditions. When selecting a regulator, think about future scalability. Will the regulator handle increased flow rates or pressure ranges if your system expands? Investing in a regulator with a broader operating envelope can save time and money down the line. Why Choose Beaumont Manufacturing and Distribution? At Beaumont Manufacturing and Distribution, we specialize in high-quality regulators and valves tailored to the needs of the oil and gas industry. Our products are built to withstand harsh environments, provide precise control, and ensure reliable operation. Whether you’re looking for pressure-reducing regulators, back-pressure regulators, or specialty models, our team is here to help you find the perfect solution for your system. With a focus on durability, safety, and efficiency, we take pride in delivering products that exceed industry standards. For more information on our regulator offerings and expert guidance, visit our Regulators Product Page . By carefully evaluating the factors outlined above, you can ensure your regulator selection enhances system performance, minimizes risks, and supports long-term operational goals. Contact Beaumont Manufacturing and Distribution today to discuss your specific requirements and find the perfect regulator for your needs. At Beaumont Manufacturing and Distribution, we understand the challenges of the oil and gas industry. Our high-quality valves and regulators are designed to meet the demands of even the most rigorous applications.

March 3, 2025

At Beaumont Manufacturing and Distribution (BMD), innovation and quality are at the core of everything we do. By achieving certifications like ISO 9001:2015, ISO 15848-1:2015, and compliance with Quad O regulations, we demonstrate our commitment to delivering high-performing, environmentally sustainable solutions for the oil and gas industry. These standards not only validate the reliability and durability of our products but also reinforce our mission to minimize fugitive emissions, enhance operational efficiency, and align with the highest industry benchmarks for quality and environmental responsibility. Let’s explore each of these certifications and standards. ISO 9001:2015 – Quality Management System ISO 9001:2015 is an internationally recognized standard for Quality Management Systems (QMS). It provides a framework for organizations to ensure consistent quality in their products or services while improving customer satisfaction and operational efficiency. Businesses that are ISO 9001 certified are audited yearly to keep in good standing to hold this distinguished certification. The standard focuses on principles such as: Customer Focus: Understanding and meeting customer needs and striving to exceed expectations. Leadership: Establishing a clear vision and creating an environment that encourages team involvement. Engagement of People: Ensuring everyone in the organization is engaged, competent, and motivated to contribute to its success. Process Approach: Managing activities and resources as processes to achieve consistent and predictable outcomes. Improvement: Continually improving processes, products, and services. Evidence-Based Decision Making: Using data and analysis to make informed decisions. Relationship Management: Fostering strong relationships with suppliers, customers, and stakeholders. Organizations certified under ISO 9001:2015 demonstrate their ability to consistently deliver high-quality products or services while maintaining a commitment to continual improvement. It applies to businesses of all sizes and industries. BMD ISO 9001:2015 Certification Beaumont Manufacturing and Distribution (BMD), is certified by ISO 9001:2015, the international gold standard for Quality Management Systems. This certification reflects our rigorous processes for designing, manufacturing, and distributing valves and controls, ensuring customers receive reliable, high-quality products. Through continuous improvements, we deliver superior performance that meets and exceeds customer expectations, while adhering to strict industry requirements. ISO 15848-1:2015 – Fugitive Emissions Standards Fugitive emissions are a growing concern in the oil and gas industry due to their environmental and regulatory implications. ISO 15848-1:2015 is an internationally recognized standard that defines the measurement, testing, and qualification procedures for fugitive emissions from industrial valves. Fugitive emissions refer to the unintended release of gases or liquids, often harmful, from valves and other equipment into the environment. This standard focuses on reducing these emissions to improve environmental safety and meet strict regulatory requirements. Key Aspects of ISO 15848-1:2015: Tightness Classes: Specifies leakage limits (e.g., parts per million by volume or ppmv) based on the level of emissions allowed. The tightest class (e.g., AM) permits less than 50 ppmv leakage. Cycle Classes: Defines how many operational cycles (e.g., open/close) a valve must endure while maintaining its tightness. Classes range from: CC1: 20,000 cycles CC2: 60,000 cycles CC3: 100,000 cycles Testing Requirements: Valves must be tested in third-party laboratories under controlled conditions to ensure they meet the leakage and durability requirements. Focus on Environmental Sustainability: Supports industries in complying with stricter regulations by minimizing harmful emissions, such as greenhouse gases, which contribute to climate change. Importance in Industry: Environmental Compliance: Helps companies meet local and international environmental regulations. Operational Efficiency: Reduces maintenance costs and downtime by using robust, high-quality valve packing systems. Sustainability Goals: Supports initiatives to lower emissions and reduce the carbon footprint of industrial operations. BMD ISO 15848-1-certified At BMD, valves equipped with ISO 15848-1-certified fugitive emissions packing ensure top performance while aligning with environmental standards, providing durability, reliability, and compliance with global emissions regulations. View all BMD control valves here. More About Innovative Packing Solutions for Reduced Emissions BMD’s patent-pending packing design uses alternating layers of engineered composite materials and live-loaded spring mechanisms to create a durable, leak-tight seal. Certified to stringent standards such as ISO 15848-1, this solution provides long cycle life, reduced maintenance, and significant reductions in greenhouse gas emissions, supporting sustainability goals while lowering operational costs BMD’s patented packing technology offers unmatched performance and reliability. Key features include: High Cycle Life: BMD valves are CC3 rated, or tested to over 100,000 cycles. Our packing ensures longevity and reduced maintenance costs. Tightest Leak Class: Achieving the AM class, with leakage below 50 ppmv, minimizes emissions and meets environmental regulations, such as Quad O standards. Spring-Loaded Design: With components like live load springs and spherical washers, our packing maintains consistent sealing performance over time. Extensive Testing for Proven Results BMD’s products undergo rigorous third-party testing to ensure compliance with ISO 15848-1 standards. These tests validate the durability and performance of our packing materials, allowing us to confidently implement them across our entire control valve product line. This commitment to quality testing not only ensures product reliability but also helps our customers reduce costs associated with frequent maintenance and emissions monitoring. Environmental and Financial Benefits By preventing fugitive emissions, BMD’s ISO 15848-certified packing reduces environmental impact while aligning with industry sustainability goals. Customers also benefit from cost savings by avoiding penalties related to emissions regulations and minimizing maintenance downtime. Under the new Quad O standard monthly LDAR inspections are needed if more than 2% of valves and devices are leaking over 500 ppm. This is reduced to quarterly LDAR if less than 1% of devices are leaking, with requirements decreasing as the number of leaking devices declines. Upgrading to superior packing to prevent leaks can save considerable time and expense. Conclusion To summarize these certifications: ISO 9001:2015 focuses on quality management systems, ensuring that BMD’s products are designed, manufactured, and distributed consistently to meet or exceed customer expectations. ISO 15848-1:2015 addresses fugitive emissions, certifying that BMD’s valve packing solutions effectively prevent leaks, comply with global environmental standards, and maintain a tight seal even under demanding operational cycles. Quad O regulations (New Source Performance Standards) are specific to oil and gas operations, targeting reductions in methane emissions through strict leak detection and repair (LDAR) protocols. Together, these certifications establish BMD as a trusted partner for safe, sustainable, and efficient solutions in oil and gas operations.

December 30, 2024

In the oil and gas industry, emissions control is a priority. Regulatory changes and a focus on sustainability have made the choice between venting and non-venting regulators more critical than ever. BMD is here to provide an understanding of the differences and offer innovative solutions for reducing carbon emissions. Understanding Venting Regulators in Oil and Gas Venting regulators, such as BMD’s BP50 and PR50 lines, are pilot-operated devices. These regulators function like valves, using a small regulator on top to control the main valve’s position. Each time the valve adjusts, it releases a small amount of gas, commonly referred to as venting. This design was typical in older regulators when environmental regulations were less stringent. Impact on Emissions Venting regulators are often used in production equipment like separators, compressors , and dehydration units. While effective at managing pressure, their operation contributes to natural gas emissions, which has significant environmental impacts. Before the introduction of regulations like Quad O and its successors (Quad Oa, Ob, and Oc), this venting was largely overlooked. Today, stricter controls on natural gas emissions make venting regulators less desirable in new installations. Venting Regulators in Various Industries Venting regulators play a crucial role in maintaining safe and efficient operations across various oil and gas facilities. These devices are typically used in systems that require precise pressure control to ensure optimal performance. Common applications include drilling rigs, refineries, and pipeline systems. In production equipment, venting regulators are often installed on separators, dehydration units, and heater treaters. For example, a BP50 back pressure valve might be used to maintain a consistent pressure in a storage tank, allowing gas to vent as needed to avoid exceeding the set pressure limit. Similarly, in amine units, venting regulators help manage the pressure fluctuations during chemical processing. These regulators are essential in scenarios where venting small amounts of gas is necessary to maintain system balance and prevent overpressure. However, as emissions regulations like Quad O become stricter, many operators are transitioning to non-venting solutions to reduce environmental impact and comply with industry standards. Non-Venting Regulators: The Sustainable Choice for Oil and Gas Non-venting regulators manage pressure without releasing gas into the atmosphere. BMD’s non-venting versions of the RG10, RG20, and RG50 redirect the gas used in valve operations back into the downstream system. This design eliminates emissions without requiring retrofits or conversion kits, unlike some competitors. Benefits of Emissions Control Non-venting regulators are crucial for complying with EPA standards under Quad O regulations. By preventing natural gas release, these regulators support sustainability initiatives and help operators avoid penalties for non-compliance. This design change aligns with industry goals to reduce environmental impacts while maintaining operational efficiency. Advantages in Oil and Gas Operations Beyond emissions control, non-venting regulators offer cost savings. By capturing and redirecting gas, operators retain more product for sale. This feature contributes to overall efficiency and reduces waste. BMD considers these regulators a step toward sustainability, emphasizing their role in helping companies meet modern environmental standards. Converting to Sustainability and Compliance with BMD In the oil and gas industry, retrofitting existing equipment is often necessary to meet evolving emissions standards. While BMD’s BP50 and PR50 regulators are designed as non-venting from the start, many legacy systems in the field still rely on venting models. To bridge this gap, BMD offers a conversion kit that transforms venting regulators into non-venting ones. This kit is particularly useful for retrofitting regulators from major competitors, ensuring they comply with current emissions regulations like Quad O. The conversion process redirects gas that would typically be vented, channeling it back into the system downstream. This not only reduces natural gas emissions but also aligns with sustainability goals. By offering both ready-to-install non-venting regulators and retrofit kits, BMD provides flexible solutions for operators looking to modernize their equipment and minimize environmental impact. Conclusion The transition from venting to non-venting regulators is a pivotal shift in the oil and gas industry. BMD’s non-venting solutions and conversion kits provide effective ways to reduce emissions, comply with regulations, and improve operational efficiency. By choosing non-venting regulators, companies not only enhance their sustainability efforts but also position themselves for long-term success in a rapidly evolving industry.

December 2, 2024

In the oil and gas industry, emissions control is a priority. Regulatory changes and a focus on sustainability have made the choice between venting and non-venting regulators more critical than ever. BMD is here to provide an understanding of the differences and offer innovative solutions for reducing carbon emissions. Understanding Venting Regulators in Oil and Gas Venting regulators, such as BMD’s BP50 and PR50 lines, are pilot-operated devices. These regulators function like valves, using a small regulator on top to control the main valve’s position. Each time the valve adjusts, it releases a small amount of gas, commonly referred to as venting. This design was typical in older regulators when environmental regulations were less stringent. Impact on Emissions Venting regulators are often used in production equipment like separators, compressors , and dehydration units. While effective at managing pressure, their operation contributes to natural gas emissions, which has significant environmental impacts. Before the introduction of regulations like Quad O and its successors (Quad Oa, Ob, and Oc), this venting was largely overlooked. Today, stricter controls on natural gas emissions make venting regulators less desirable in new installations. Venting Regulators in Various Industries Venting regulators play a crucial role in maintaining safe and efficient operations across various oil and gas facilities. These devices are typically used in systems that require precise pressure control to ensure optimal performance. Common applications include drilling rigs, refineries, and pipeline systems. In production equipment, venting regulators are often installed on separators, dehydration units, and heater treaters. For example, a BP50 back pressure valve might be used to maintain a consistent pressure in a storage tank, allowing gas to vent as needed to avoid exceeding the set pressure limit. Similarly, in amine units, venting regulators help manage the pressure fluctuations during chemical processing. These regulators are essential in scenarios where venting small amounts of gas is necessary to maintain system balance and prevent overpressure. However, as emissions regulations like Quad O become stricter, many operators are transitioning to non-venting solutions to reduce environmental impact and comply with industry standards. Non-Venting Regulators: The Sustainable Choice for Oil and Gas Non-venting regulators manage pressure without releasing gas into the atmosphere. BMD’s non-venting versions of the RG10, RG20, and RG50 redirect the gas used in valve operations back into the downstream system. This design eliminates emissions without requiring retrofits or conversion kits, unlike some competitors. Benefits of Emissions Control Non-venting regulators are crucial for complying with EPA standards under Quad O regulations. By preventing natural gas release, these regulators support sustainability initiatives and help operators avoid penalties for non-compliance. This design change aligns with industry goals to reduce environmental impacts while maintaining operational efficiency. Advantages in Oil and Gas Operations Beyond emissions control, non-venting regulators offer cost savings. By capturing and redirecting gas, operators retain more product for sale. This feature contributes to overall efficiency and reduces waste. BMD considers these regulators a step toward sustainability, emphasizing their role in helping companies meet modern environmental standards. Converting to Sustainability and Compliance with BMD In the oil and gas industry, retrofitting existing equipment is often necessary to meet evolving emissions standards. While BMD’s BP50 and PR50 regulators are designed as non-venting from the start, many legacy systems in the field still rely on venting models. To bridge this gap, BMD offers a conversion kit that transforms venting regulators into non-venting ones. This kit is particularly useful for retrofitting regulators from major competitors, ensuring they comply with current emissions regulations like Quad O. The conversion process redirects gas that would typically be vented, channeling it back into the system downstream. This not only reduces natural gas emissions but also aligns with sustainability goals. By offering both ready-to-install non-venting regulators and retrofit kits, BMD provides flexible solutions for operators looking to modernize their equipment and minimize environmental impact. Conclusion The transition from venting to non-venting regulators is a pivotal shift in the oil and gas industry. BMD’s non-venting solutions and conversion kits provide effective ways to reduce emissions, comply with regulations, and improve operational efficiency. By choosing non-venting regulators, companies not only enhance their sustainability efforts but also position themselves for long-term success in a rapidly evolving industry.

November 29, 2024

The natural gas industry plays a critical role in today’s energy landscape, offering a cleaner, more efficient alternative to traditional fossil fuels like coal and diesel fuel. In recent years, this alternative fuel source has gained traction across various sectors, from power generation to transportation. However, the efficient movement of natural gas relies heavily on natural gas compression—a process that ensures this essential fuel travels long distances effectively. Without compression, the transportation of natural gas would face significant challenges, including higher costs and increased environmental impact. The Shift to Natural Gas Engines: A Growing Trend The transition from diesel engines to natural gas engines marks a significant shift in mass transit and industrial applications. Natural gas vehicles are becoming increasingly common, offering lower greenhouse gas emissions and reduced particulate matter compared to traditional fuel sources. Additionally, renewable natural gas and compressed natural gas (CNG) have paved the way for new advancements in vehicle fuel technology. Natural gas compression plays a vital role in this movement. By increasing the gas pressure at compressor stations, natural gas can be stored in smaller volumes, transported in CNG tanks, or delivered efficiently to fast-fill stations and time-fill stations for use in various industries. This transition not only supports sustainability but also enables greater efficiency in fuel transportation and storage. The Mechanics of Natural Gas Compression and Transport Natural gas compressors are essential for the movement of natural gas through pipelines and other transport systems. These units operate by increasing the pressure of natural gas to make it easier to store and move. At a natural gas compressor station, the gas undergoes a compression process to achieve the necessary pressure for efficient transportation. There are various types of compressors, including rotary screw compressors, reciprocating compressors, and centrifugal compressors, each designed for specific applications. For instance, positive displacement compressors are often used in smaller-scale operations, while larger compressors manage the higher pressures required for industrial uses. Compressor stations are strategically located along pipeline routes or at wellheads to ensure the smooth transportation of natural gas. These stations reduce the gas volume, allowing it to be stored in high-pressure cylinders or transported in liquid form (LNG). This compression process is crucial for overcoming long distances and ensuring natural gas reaches its destination without significant loss of quality or efficiency. Understanding Natural Gas Compression Services Natural gas compression services are vital for preparing natural gas for use in various applications. Raw natural gas extracted from the ground often contains impurities like carbon dioxide, water vapor, and particulate matter. Before it can be used as a fuel source, it must undergo a series of processes to meet quality standards. The first stage of compression often involves removing contaminants and increasing the gas pressure to standard atmospheric pressure. In some cases, the gas undergoes further distillation, separating it into components like natural gas liquids, which are used in industrial and commercial applications. By utilizing advanced compression stages, including diaphragm compressors and rotary screw compressors, the natural gas industry achieves higher efficiency in preparing gas for diverse applications. These processes are not just about making gas usable; they also contribute to reducing maintenance costs, improving environmental impact, and enabling the use of CNG infrastructure, such as CNG stations and high-pressure storage tanks. The Future of Natural Gas Compression As the demand for alternative fuel sources grows, natural gas compression remains at the forefront of innovation. Advancements in compressor mechanics, including the use of composite materials and improved compression ratios, are enabling greater efficiency and reduced environmental impact. Natural gas compression packages are becoming more sophisticated, catering to specific applications with features like suction control valves and electric motors for enhanced performance. The shift toward natural gas as a primary fuel source is driven by its versatility and lower greenhouse gas emissions . From powering gas engines to supporting renewable energy initiatives, the transportation of natural gas through efficient compression systems is essential for meeting the energy demands of the future. Whether used in commercial applications, power generation, or industrial processes, natural gas compression services ensure the movement of natural gas continues to be a reliable and sustainable solution. Efficiency and Environmental Impact of Natural Gas with Beaumont Manufacturing and Distribution Beaumont Manufacturing and Distribution (BMD) is leading the charge in making natural gas compression a more sustainable and environmentally friendly process. By focusing on advanced technology and eco-conscious practices, BMD helps reduce the environmental impact of natural gas transportation while enhancing efficiency and cutting costs. Comparison of Natural Gas to Diesel Fuel: A Cleaner Alternative Natural gas is already a cleaner fuel source compared to traditional fossil fuels like diesel fuel. With the rise of renewable natural gas, the benefits are even more pronounced. Unlike diesel, natural gas produces significantly fewer greenhouse gas emissions and particulate matter, making it a better choice for the environment. This cleaner-burning fuel is essential in reducing the environmental impact of mass transit, industrial uses, and natural gas vehicles. BMD ensures that the natural gas compression process aligns with these environmental benefits. By integrating compressors that use the same gas they compress as fuel, BMD eliminates the need for external fuel sources like diesel, further reducing emissions and simplifying operations. The Role of High-Efficiency Compressors in Sustainability BMD’s compressors are designed with sustainability and efficiency in mind. These high-efficiency compressors contribute to lower emissions, longer operational lifespans, and reduced maintenance costs. Automated Operations for Greater Efficiency BMD’s compressors are fully automated, using advanced computer systems to optimize performance. Automation minimizes energy waste during the compression process, ensuring the gas pressure is achieved with the least energy expenditure. Zero-Emissions Packing and Vent-Free Valves To comply with stringent environmental standards like 0000 B/C compliance, BMD offers zero-emissions packing and vent-free valves . These features capture emissions during the compression process, reducing the release of harmful greenhouse gases and maintaining compliance with regulatory requirements. Durable Components for Reduced Maintenance Longer-lasting valves and innovative materials ensure that BMD’s compressors require less frequent maintenance. This not only lowers costs but also reduces downtime, ensuring consistent efficiency throughout the system. Energy Efficiency: Using Natural Gas to Compress Natural Gas One of the most innovative aspects of BMD’s compression systems is the ability to use natural gas as both the fuel and the compressed product. This self-sustaining process eliminates the need for external energy sources like diesel tanks, cutting down on logistical costs and emissions. Wildly Efficient Compression A portion of the natural gas extracted is burned by the engine to compress the remaining gas. This closed-loop system enhances energy efficiency, as the compressors essentially run on the same fuel they process. Cost-Effective Operations By using the natural gas already in the system, BMD compressors eliminate the need to transport additional fuel. This results in lower maintenance costs and reduced carbon emissions, aligning with the push toward alternative fuel sources. Beaumont Manufacturing and Distribution’s commitment to sustainability extends across its operations. By employing innovative compressor mechanics and focusing on compliance with environmental standards, BMD ensures that natural gas remains a cleaner and more efficient fuel source for various applications. Our high-pressure compressors, automated processes, and eco-friendly features set us apart as leaders in the natural gas industry, making the transportation of CNG and LNG as environmentally friendly as possible. Conclusion The mechanics of natural gas compressors and the services they provide are critical to the movement of natural gas. By enabling the transportation of CNG and LNG, these systems support the natural gas industry’s efforts to deliver a cleaner, more efficient fuel source. As advancements continue, the role of natural gas compression in various industries will only grow, ensuring this vital resource meets the world’s energy needs.