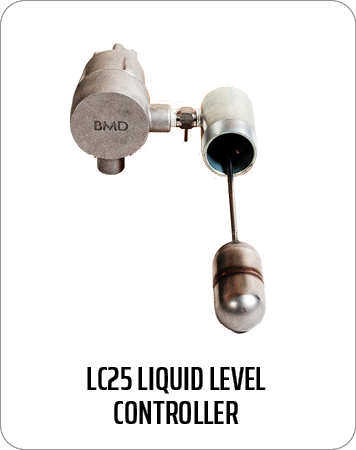

LC25

Liquid Level Controller

The LC25 is a low-pressure, float operated, liquid level switch.

- Low-pressure Liquid Level Switch

- Float-operated

- Working pressure of up to 200 PSI

- Features a rugged aluminum housing containing a SPDT switch

- Can be wired to either make or break contact when the liquid level rises or falls

| Specifications | |||||

|---|---|---|---|---|---|

| Sizes: | 2” NPT | ||||

| Pressure Rating: | 200 psi | ||||

| Temperature Range: | -20° F to 400° F | (-29° C to 204° C) | |||

| Electric Switch Ratings: | 15A @ 125, 250, 480 VAC | 1/8 HP @ 125 VAC | 1/4A @ 250 VDC | 1/4 HP @ 250 VAC | 1/2A @ 125 VDC |

| Materials | |

|---|---|

| Housing: | Cast Aluminum |

| Body: | Zinc Plated Carbon Steel |

| Float: | 304 Stainless Steel |

| Arm: | 304 Stainless Steel |

| Shaft: | Dry Film Lubricated Stainless Steel |

| Seals: | Viton® |

| Pilot Body: | Aluminum |

Find the right valve for your project with our custom builder

Contact sales to start your purchase for your next project

Related Articles & Training

By Website Editor

•

May 16, 2025

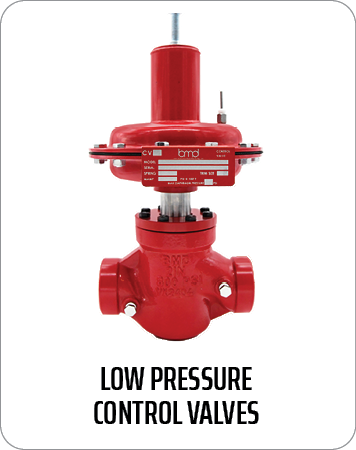

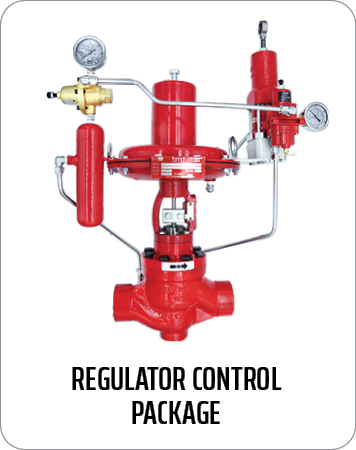

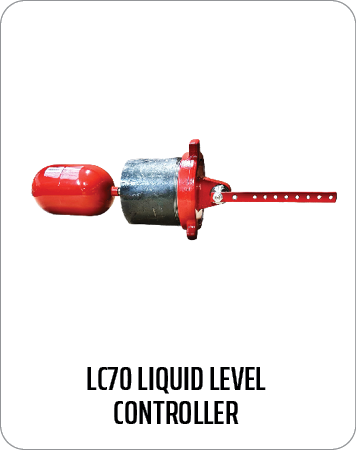

Introduction In oil and gas production facilities, flow and level control are critical for maintaining operational integrity, optimizing production rates, and ensuring equipment protection. Flow control involves regulating the movement of oil, gas, water, and other fluids through pipelines and processing equipment. This is typically achieved using specialized control valves that adjust the rate and pressure of flow based on real-time operational requirements. Level controls, on the other hand, ensure that liquid levels in storage tanks or process vessels stay within specified limits to avoid overflow, underflow,, which can lead to hazardous situations or damage equipment. Flow and level control are interdependent. For example, an increased liquid discharge rate without corresponding flow control adjustments can destabilize separator pressure regimes, affecting downstream gas handling systems. Similarly, changes in flow rates can impact fluid levels in storage tanks. Therefore, precise and dynamic integration of these controls is mandatory to avoid process upsets due to unstable flow rates, fluctuating pressure levels, or unsafe liquid levels. Improper valve actuation or sluggish level control can lead to severe consequences, including over-pressurization, hydrocarbon release, inefficient separation, and mechanical failures. In the inherently hazardous oil and gas sector, accurate level control plays a crucial role in safeguarding operations while optimizing efficiency. Beaumont Manufacturing and Distribution Company (BMD), specializes in high quality level and flow control solutions. BMD’s high-quality, precision-engineered flow and level control solutions reflect our innovative engineering and deep understanding of hydrocarbon production environments. This article highlights how Beaumont Manufacturing and Distribution’s (BMD) advanced control valves and level controls work together seamlessly to provide precise and dependable solutions for oil and gas production operations. BMD’s Role in Flow and Level Management Beaumont Manufacturing and Distribution Company (BMD), based in Texas, is renowned for its rugged control valves, extensively utilized for managing flow, pressure, and level control in upstream and midstream service. BMD combines innovative engineering with a steadfast commitment to quality and environmental protection. Every model features fugitive emission packing to eliminate leaks, reflecting our dedication to smart and sustainable solutions. With advanced manufacturing facilities in Texas, we ensure superior product quality. Rooted in integrity and excellence, we foster strong partnerships and deliver dependable results, driving our clients’ missions forward with ingenuity. BMD takes pride in being a service-focused, innovative company that harnesses field experience and practical, lean engineering. Our mission has always been to support technicians in optimizing production processes. Oil and gas operators quickly recognize the value of BMD’s dependable level and flow control products, which ensure precision control and optimize operations. With distinctive features such as force-balanced design, quick-open trim, bubble-tight shut-off, and fugitive emissions packing, our control valves have consistently demonstrated their exceptional performance in upstream and midstream production environments. BMD offers a versatile range of pneumatic control valves designed for both high- and low-pressure applications, featuring cage-guided, non-freeze, and stem-guided options. These valves seamlessly integrate with our extensive selection of pneumatic and mechanical level controllers, which utilize float or displacer-type level sensors. Together, these integrated systems are deployed in critical applications, including separators, scrubbers, and various production vessels. What Are Control Valves and How Does BMD Design Them? Control valves are the final control elements in automatic control loops that regulate fluid flow to ensure stable operating conditions in oil and gas equipment such as separators, scrubbers, tanks and other process vessels. They function by varying the flow area through the valve trim—consisting of the plug, seat, and stem—tailored to flow characteristics like linear or quick opening. Actuators adjust the plug position based on controller signals, changing the opening size and enabling precise, predictable control of fluid movement for optimal performance. BMD provides an extensive selection of control valves tailored for oil and gas applications, suitable for diverse pressure, temperature, and flow control needs. Key features are as follows: Pressure Rating: BMD control valves are categorized into high-pressure and low-pressure variants. High-pressure control valves are rated up to ANSI 1500# for valve sizes up to 4 inches, whereas high-pressure valves with a size of 6 inches are available with an ANSI rating of up to 600#. BMD low-pressure valves are offered in pressure ratings of 250 psi, 300 psi, and 500 psi for sizes up to 4 inches. Material Selection: BMD control valves are manufactured from carefully selected materials to address critical factors such as sour service, corrosion resistance, erosion resistance, and operational conditions, including pressure and temperature. Valve bodies are primarily made from ASTM A216 WCC for standard applications and ASTM A352 LCC for low-temperature environments. Valve trims are offered in various stainless-steel grades, such as 440C, 316, and 304, with specialized carbide trims providing enhanced erosion resistance. Packing plugs are generally manufactured from nickel- or zinc-plated ASTM A105 steel, ensuring durability and reliable performance. Leakage Class: All our high-pressure valves are rated to meet at minimum ANSI Class IV leakage standard, which represents the industry benchmark for metal-seated oil and gas control valves. BMD’s high- pressure CV30 model is available with a soft seat option rated for ANSI Class VI, while all the low-pressure valves are available with soft seats, ensuring leak-lightness at shutoff. Valve Flow Characteristics: BMD control valves are offered with Equal Percent, Linear, and Quick Open characteristics, catering to control requirements ranging from precise modulation to rapid discharge actions. Additionally, we provide valve models with modified percentage characteristics, designed for applications that require accurate throttling at low capacities while ensuring consistent performance at higher capacities. Actuation: All BMD control valves are designed for pneumatic actuation. Standout examples demonstrating BMD’s expertise in combining innovative design with robust construction are the CV10/CV15 control valve models. These compact, cage-guided valves are designed for a wide range of applications, including pressure, level, and flow control. Their unique design makes them ideal for wellhead service as well as conventional level control applications in separators, scrubbers, and other production equipment. The CV10/CV15 design features a hammer union that simplifies maintenance by enabling the topworks to be removed without taking the valve out of line. For sour service, a NACE-compliant option is available. For abrasive conditions, such as oil and gas wells with high sand concentrations in the flow, the CV10/CV15 can be equipped with a sand body and a replaceable plug, ensuring enhanced durability and reliability. The CV10 is a close coupled designed and the CV15 is an open yoke design as shown in Figure 1. What Are Level Controls and What Does BMD Offer? BMD level controllers measure liquid levels using sensors such as floats or displacers. The float-type sensor relies on a buoyant device attached to a lever or linkage that moves as the liquid level changes. This movement is transmitted to the control mechanism, which sends a pneumatic or electrical signal to the level control valve. These signals cause the valve to open or close, regulating the outflow of liquid to maintain the desired level. Similarly, the displacer-type level controller operates on the same principle. It uses a displacer suspended in the liquid. As the liquid level changes, the buoyant force acting on the displacer varies, causing movement in the sensing mechanism. This movement generates a pneumatic or electric signal to adjust the control valve. BMD also offers a purely mechanical level controller. The LC70 level controller features a large float, linkage rod, and levers to mechanically operate a dump valve through rotational connections. Paired with BMD’s CV45 mechanical valve, the LC70 offers a cost-effective, emissions-free level control and dump system, since the control valve does not need a separate actuator. Figure 2 shows a typical level control arrangement using the BMD LC70/CV45 combination.

March 3, 2025

At Beaumont Manufacturing and Distribution (BMD), innovation and quality are at the core of everything we do. By achieving certifications like ISO 9001:2015, ISO 15848-1:2015, and compliance with Quad O regulations, we demonstrate our commitment to delivering high-performing, environmentally sustainable solutions for the oil and gas industry. These standards not only validate the reliability and durability of our products but also reinforce our mission to minimize fugitive emissions, enhance operational efficiency, and align with the highest industry benchmarks for quality and environmental responsibility. Let’s explore each of these certifications and standards. ISO 9001:2015 – Quality Management System ISO 9001:2015 is an internationally recognized standard for Quality Management Systems (QMS). It provides a framework for organizations to ensure consistent quality in their products or services while improving customer satisfaction and operational efficiency. Businesses that are ISO 9001 certified are audited yearly to keep in good standing to hold this distinguished certification. The standard focuses on principles such as: Customer Focus: Understanding and meeting customer needs and striving to exceed expectations. Leadership: Establishing a clear vision and creating an environment that encourages team involvement. Engagement of People: Ensuring everyone in the organization is engaged, competent, and motivated to contribute to its success. Process Approach: Managing activities and resources as processes to achieve consistent and predictable outcomes. Improvement: Continually improving processes, products, and services. Evidence-Based Decision Making: Using data and analysis to make informed decisions. Relationship Management: Fostering strong relationships with suppliers, customers, and stakeholders. Organizations certified under ISO 9001:2015 demonstrate their ability to consistently deliver high-quality products or services while maintaining a commitment to continual improvement. It applies to businesses of all sizes and industries. BMD ISO 9001:2015 Certification Beaumont Manufacturing and Distribution (BMD), is certified by ISO 9001:2015, the international gold standard for Quality Management Systems. This certification reflects our rigorous processes for designing, manufacturing, and distributing valves and controls, ensuring customers receive reliable, high-quality products. Through continuous improvements, we deliver superior performance that meets and exceeds customer expectations, while adhering to strict industry requirements. ISO 15848-1:2015 – Fugitive Emissions Standards Fugitive emissions are a growing concern in the oil and gas industry due to their environmental and regulatory implications. ISO 15848-1:2015 is an internationally recognized standard that defines the measurement, testing, and qualification procedures for fugitive emissions from industrial valves. Fugitive emissions refer to the unintended release of gases or liquids, often harmful, from valves and other equipment into the environment. This standard focuses on reducing these emissions to improve environmental safety and meet strict regulatory requirements. Key Aspects of ISO 15848-1:2015: Tightness Classes: Specifies leakage limits (e.g., parts per million by volume or ppmv) based on the level of emissions allowed. The tightest class (e.g., AM) permits less than 50 ppmv leakage. Cycle Classes: Defines how many operational cycles (e.g., open/close) a valve must endure while maintaining its tightness. Classes range from: CC1: 20,000 cycles CC2: 60,000 cycles CC3: 100,000 cycles Testing Requirements: Valves must be tested in third-party laboratories under controlled conditions to ensure they meet the leakage and durability requirements. Focus on Environmental Sustainability: Supports industries in complying with stricter regulations by minimizing harmful emissions, such as greenhouse gases, which contribute to climate change. Importance in Industry: Environmental Compliance: Helps companies meet local and international environmental regulations. Operational Efficiency: Reduces maintenance costs and downtime by using robust, high-quality valve packing systems. Sustainability Goals: Supports initiatives to lower emissions and reduce the carbon footprint of industrial operations. BMD ISO 15848-1-certified At BMD, valves equipped with ISO 15848-1-certified fugitive emissions packing ensure top performance while aligning with environmental standards, providing durability, reliability, and compliance with global emissions regulations. View all BMD control valves here. More About Innovative Packing Solutions for Reduced Emissions BMD’s patent-pending packing design uses alternating layers of engineered composite materials and live-loaded spring mechanisms to create a durable, leak-tight seal. Certified to stringent standards such as ISO 15848-1, this solution provides long cycle life, reduced maintenance, and significant reductions in greenhouse gas emissions, supporting sustainability goals while lowering operational costs BMD’s patented packing technology offers unmatched performance and reliability. Key features include: High Cycle Life: BMD valves are CC3 rated, or tested to over 100,000 cycles. Our packing ensures longevity and reduced maintenance costs. Tightest Leak Class: Achieving the AM class, with leakage below 50 ppmv, minimizes emissions and meets environmental regulations, such as Quad O standards. Spring-Loaded Design: With components like live load springs and spherical washers, our packing maintains consistent sealing performance over time. Extensive Testing for Proven Results BMD’s products undergo rigorous third-party testing to ensure compliance with ISO 15848-1 standards. These tests validate the durability and performance of our packing materials, allowing us to confidently implement them across our entire control valve product line. This commitment to quality testing not only ensures product reliability but also helps our customers reduce costs associated with frequent maintenance and emissions monitoring. Environmental and Financial Benefits By preventing fugitive emissions, BMD’s ISO 15848-certified packing reduces environmental impact while aligning with industry sustainability goals. Customers also benefit from cost savings by avoiding penalties related to emissions regulations and minimizing maintenance downtime. Under the new Quad O standard monthly LDAR inspections are needed if more than 2% of valves and devices are leaking over 500 ppm. This is reduced to quarterly LDAR if less than 1% of devices are leaking, with requirements decreasing as the number of leaking devices declines. Upgrading to superior packing to prevent leaks can save considerable time and expense. Conclusion To summarize these certifications: ISO 9001:2015 focuses on quality management systems, ensuring that BMD’s products are designed, manufactured, and distributed consistently to meet or exceed customer expectations. ISO 15848-1:2015 addresses fugitive emissions, certifying that BMD’s valve packing solutions effectively prevent leaks, comply with global environmental standards, and maintain a tight seal even under demanding operational cycles. Quad O regulations (New Source Performance Standards) are specific to oil and gas operations, targeting reductions in methane emissions through strict leak detection and repair (LDAR) protocols. Together, these certifications establish BMD as a trusted partner for safe, sustainable, and efficient solutions in oil and gas operations.

January 20, 2025

Introduction: Mechanical Level Controller Preventing downtime in oil production is a critical goal for operational efficiency. Integrating reliable control valves and level control systems, such as the LC70 float-operated liquid level controller, plays a key role in avoiding costly interruptions. This blog post explores how these systems work and their advantages in maintaining smooth operations. Go here to view all of the Level Controls at Beaumont Manufacturing and Distribution. How Control Valves and Level Controllers Work Control valves and level controllers are critical in oil production, particularly in vessels like separators and compressors . These systems regulate liquid levels, ensuring vessels operate safely and efficiently. Mechanical level controllers operate through simple, robust designs, using mechanical components like splines, gears, and arms to communicate with a control valve (or dump valve). This design eliminates the need for complex electronics or pneumatic systems, reducing the risk of malfunctions. In summary, because they’re so simple, there’s less that can go wrong. Let’s dive into these advantages in more detail. Advantages of the Mechanical Level Controller Reliability Mechanical level controllers are inherently reliable due to their straightforward design. With no reliance on electronics or air systems, they are less prone to failure compared to more complex alternatives. The simplicity ensures reliability by minimizing potential points of failure. With no air to cause leaks, no lines to clog, and a solid-state design, these systems eliminate many common issues found in more complex setups. Unlike more complex electronic systems, the LC70 operates through a purely mechanical design composed of two steel arms connected by a lever. This straightforward mechanism eliminates the need for components like diaphragms, air lines, or intricate electronic parts, significantly reducing the risk of failure. The absence of these potential weak points means there are fewer parts to break or malfunction, creating a system that requires minimal maintenance. Its solid-state design ensures consistent performance, making it an ideal solution for operations where reliability is critical and downtime must be avoided. Durability The absence of air lines or electronic components prevents common issues like leaks, clogs, or electronic malfunctions. Their solid-state design ensures long-term durability even in demanding environments. Ease of Maintenance and Preventing Downtime Mechanical controllers are simple to inspect, repair, and maintain. Fewer components mean fewer potential failures and reduced downtime for maintenance. Mechanical level controllers also prevent downtime by offering long intervals between rebuilds and avoiding frequent rework issues. For example, many brands struggle with problems like washed-out valve seats or imbalanced packs, which lead to significant delays. Mechanical controllers avoid these pitfalls, helping operators maintain continuous production and reduce costly inefficiencies. Mechanical Level Controller and Emissions Unlike pneumatic systems that vent pressurized gas, mechanical level controllers operate without emissions, aligning with environmental regulations and sustainability goals. Pneumatic systems often release natural gas or other pressurized gases into the atmosphere during operation, contributing to greenhouse gas emissions. Mechanical level controllers avoid this issue entirely by using a purely mechanical design with no air-powered mechanisms, eliminating the possibility of such emissions. This advantage allows mechanical level controllers to comply with increasingly stringent environmental regulations, such as Quad 0000b/c. Their emissions-free operation reduces environmental impact and offers potential cost savings by avoiding fines or penalties associated with excessive emissions. These qualities also align with broader sustainability goals, making mechanical level controllers a preferred choice for environmentally conscious operations in the oil and gas industry. Considerations When Selecting a Mechanical Level Controller While mechanical level controllers are robust and reliable, there are limitations to consider: Pressure Handling: Mechanical controllers may be less effective in extremely high-pressure applications due to their mechanical design. Sensitivity: They typically lack the precision of electronic systems in detecting small liquid level changes. Flow Capacity: Mechanical controllers prioritize reliability over throughput, which may limit their effectiveness in managing very high flow rates. Adaptability: They do not integrate easily with automation or remote monitoring systems, which can be a disadvantage in highly automated operations. High-Temperature Environments: Extreme heat may pose challenges to durability and could lead to material fatigue over time. While mechanical level controllers excel in simplicity, reliability, and emissions performance, these limitations mean they may not be the ideal choice for every operational context. Applications requiring high precision, advanced automation, or high-pressure tolerance might benefit from alternative solutions. Conclusion Mechanical level controllers are an excellent choice for preventing downtime in oil production. Their robust mechanical design, durability, and reliability make them valuable components for maintaining operational efficiency. By reducing the frequency of rebuilds and minimizing potential failure points, mechanical level controllers deliver consistent performance. This reliability helps operators avoid costly interruptions in production, ensuring smooth and continuous operations in demanding industrial environments.

November 29, 2024

The natural gas industry plays a critical role in today’s energy landscape, offering a cleaner, more efficient alternative to traditional fossil fuels like coal and diesel fuel. In recent years, this alternative fuel source has gained traction across various sectors, from power generation to transportation. However, the efficient movement of natural gas relies heavily on natural gas compression—a process that ensures this essential fuel travels long distances effectively. Without compression, the transportation of natural gas would face significant challenges, including higher costs and increased environmental impact. The Shift to Natural Gas Engines: A Growing Trend The transition from diesel engines to natural gas engines marks a significant shift in mass transit and industrial applications. Natural gas vehicles are becoming increasingly common, offering lower greenhouse gas emissions and reduced particulate matter compared to traditional fuel sources. Additionally, renewable natural gas and compressed natural gas (CNG) have paved the way for new advancements in vehicle fuel technology. Natural gas compression plays a vital role in this movement. By increasing the gas pressure at compressor stations, natural gas can be stored in smaller volumes, transported in CNG tanks, or delivered efficiently to fast-fill stations and time-fill stations for use in various industries. This transition not only supports sustainability but also enables greater efficiency in fuel transportation and storage. The Mechanics of Natural Gas Compression and Transport Natural gas compressors are essential for the movement of natural gas through pipelines and other transport systems. These units operate by increasing the pressure of natural gas to make it easier to store and move. At a natural gas compressor station, the gas undergoes a compression process to achieve the necessary pressure for efficient transportation. There are various types of compressors, including rotary screw compressors, reciprocating compressors, and centrifugal compressors, each designed for specific applications. For instance, positive displacement compressors are often used in smaller-scale operations, while larger compressors manage the higher pressures required for industrial uses. Compressor stations are strategically located along pipeline routes or at wellheads to ensure the smooth transportation of natural gas. These stations reduce the gas volume, allowing it to be stored in high-pressure cylinders or transported in liquid form (LNG). This compression process is crucial for overcoming long distances and ensuring natural gas reaches its destination without significant loss of quality or efficiency. Understanding Natural Gas Compression Services Natural gas compression services are vital for preparing natural gas for use in various applications. Raw natural gas extracted from the ground often contains impurities like carbon dioxide, water vapor, and particulate matter. Before it can be used as a fuel source, it must undergo a series of processes to meet quality standards. The first stage of compression often involves removing contaminants and increasing the gas pressure to standard atmospheric pressure. In some cases, the gas undergoes further distillation, separating it into components like natural gas liquids, which are used in industrial and commercial applications. By utilizing advanced compression stages, including diaphragm compressors and rotary screw compressors, the natural gas industry achieves higher efficiency in preparing gas for diverse applications. These processes are not just about making gas usable; they also contribute to reducing maintenance costs, improving environmental impact, and enabling the use of CNG infrastructure, such as CNG stations and high-pressure storage tanks. The Future of Natural Gas Compression As the demand for alternative fuel sources grows, natural gas compression remains at the forefront of innovation. Advancements in compressor mechanics, including the use of composite materials and improved compression ratios, are enabling greater efficiency and reduced environmental impact. Natural gas compression packages are becoming more sophisticated, catering to specific applications with features like suction control valves and electric motors for enhanced performance. The shift toward natural gas as a primary fuel source is driven by its versatility and lower greenhouse gas emissions . From powering gas engines to supporting renewable energy initiatives, the transportation of natural gas through efficient compression systems is essential for meeting the energy demands of the future. Whether used in commercial applications, power generation, or industrial processes, natural gas compression services ensure the movement of natural gas continues to be a reliable and sustainable solution. Efficiency and Environmental Impact of Natural Gas with Beaumont Manufacturing and Distribution Beaumont Manufacturing and Distribution (BMD) is leading the charge in making natural gas compression a more sustainable and environmentally friendly process. By focusing on advanced technology and eco-conscious practices, BMD helps reduce the environmental impact of natural gas transportation while enhancing efficiency and cutting costs. Comparison of Natural Gas to Diesel Fuel: A Cleaner Alternative Natural gas is already a cleaner fuel source compared to traditional fossil fuels like diesel fuel. With the rise of renewable natural gas, the benefits are even more pronounced. Unlike diesel, natural gas produces significantly fewer greenhouse gas emissions and particulate matter, making it a better choice for the environment. This cleaner-burning fuel is essential in reducing the environmental impact of mass transit, industrial uses, and natural gas vehicles. BMD ensures that the natural gas compression process aligns with these environmental benefits. By integrating compressors that use the same gas they compress as fuel, BMD eliminates the need for external fuel sources like diesel, further reducing emissions and simplifying operations. The Role of High-Efficiency Compressors in Sustainability BMD’s compressors are designed with sustainability and efficiency in mind. These high-efficiency compressors contribute to lower emissions, longer operational lifespans, and reduced maintenance costs. Automated Operations for Greater Efficiency BMD’s compressors are fully automated, using advanced computer systems to optimize performance. Automation minimizes energy waste during the compression process, ensuring the gas pressure is achieved with the least energy expenditure. Zero-Emissions Packing and Vent-Free Valves To comply with stringent environmental standards like 0000 B/C compliance, BMD offers zero-emissions packing and vent-free valves . These features capture emissions during the compression process, reducing the release of harmful greenhouse gases and maintaining compliance with regulatory requirements. Durable Components for Reduced Maintenance Longer-lasting valves and innovative materials ensure that BMD’s compressors require less frequent maintenance. This not only lowers costs but also reduces downtime, ensuring consistent efficiency throughout the system. Energy Efficiency: Using Natural Gas to Compress Natural Gas One of the most innovative aspects of BMD’s compression systems is the ability to use natural gas as both the fuel and the compressed product. This self-sustaining process eliminates the need for external energy sources like diesel tanks, cutting down on logistical costs and emissions. Wildly Efficient Compression A portion of the natural gas extracted is burned by the engine to compress the remaining gas. This closed-loop system enhances energy efficiency, as the compressors essentially run on the same fuel they process. Cost-Effective Operations By using the natural gas already in the system, BMD compressors eliminate the need to transport additional fuel. This results in lower maintenance costs and reduced carbon emissions, aligning with the push toward alternative fuel sources. Beaumont Manufacturing and Distribution’s commitment to sustainability extends across its operations. By employing innovative compressor mechanics and focusing on compliance with environmental standards, BMD ensures that natural gas remains a cleaner and more efficient fuel source for various applications. Our high-pressure compressors, automated processes, and eco-friendly features set us apart as leaders in the natural gas industry, making the transportation of CNG and LNG as environmentally friendly as possible. Conclusion The mechanics of natural gas compressors and the services they provide are critical to the movement of natural gas. By enabling the transportation of CNG and LNG, these systems support the natural gas industry’s efforts to deliver a cleaner, more efficient fuel source. As advancements continue, the role of natural gas compression in various industries will only grow, ensuring this vital resource meets the world’s energy needs.

October 28, 2024

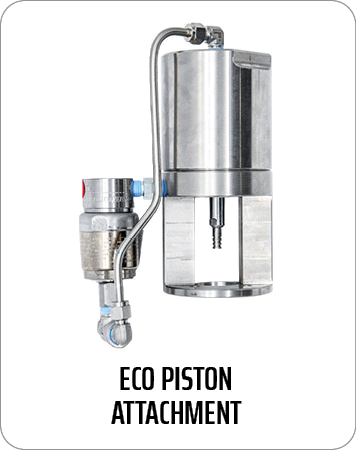

Actuator air systems play a crucial role in modern industrial applications. These systems utilize compressed air to power pneumatic actuators, enabling precise control and movement in various machinery and equipment. From single acting pneumatic actuators to complex valve actuation systems, the use of air pressure has revolutionized automation across industries. This article explores the world of actuator air systems and their components. It delves into different types of actuators used in industrial settings, examines control systems and speed controllers, and introduces the eco piston – a zero emissions actuator. By understanding these key aspects, readers will gain insight into the operation and importance of pneumatic actuation systems in today’s manufacturing and process control environments. Types of Actuators Used in Industrial Applications These devices are commonly found in manufacturing, packaging, food and beverage, and automation industries. Pneumatic actuators offer high force and speed in a compact design, making them suitable for applications requiring rapid movement and flexibility. Pneumatic actuators come in different configurations, including single-acting and double-acting types. Single-acting pneumatic actuators use air pressure to move in one direction and a spring return to return the original position. Double-acting actuators, on the other hand, employ air pressure for movement in both directions. These actuators can provide both rotational and linear motion, allowing for versatility in automated processes. Air Actuators vs. Electric Actuators When comparing pneumatic and electric actuators, pneumatic systems, like those made by BMD, have been a trusted choice for centuries, especially in industries like oil and gas. Using pressure with diaphragm and spring topworks, pneumatic actuators don’t need electric current or an air compressor, making them ideal for remote, hazardous environments. Electric actuators, while not requiring gas, need both power and an air compressor, complicating installation and maintenance, especially in isolated areas. Retrofitting electric actuators onto existing valves introduces a steep learning curve, similar to modern car technology, with potential reliability issues in remote locations. Pneumatic actuators are well-established, easier to maintain, and suited for applications requiring durability. Ball valves and butterfly valves play a key role in controlling fluid flow in both actuator systems, offering versatility in various applications. Proper mounting of solenoid valves and direct mount solenoid valves is crucial for system stability. Correct installation ensures reliable operation and prevents malfunctions, particularly in demanding environments. Choosing the right actuator depends on the specific application, with pneumatic favored for remote, rugged environments, and electric actuators offering precise control where needed.