Instrument Air Packages: Actuator Air Systems and More

Actuator air systems play a crucial role in modern industrial applications. These systems utilize compressed air to power pneumatic actuators, enabling precise control and movement in various machinery and equipment. From single acting pneumatic actuators to complex valve actuation systems, the use of air pressure has revolutionized automation across industries.

This article explores the world of actuator air systems and their components. It delves into different types of actuators used in industrial settings, examines control systems and speed controllers, and introduces the eco piston – a zero emissions actuator. By understanding these key aspects, readers will gain insight into the operation and importance of pneumatic actuation systems in today’s manufacturing and process control environments.

Types of Actuators Used in Industrial Applications

These devices are commonly found in manufacturing, packaging, food and beverage, and automation industries. Pneumatic actuators offer high force and speed in a compact design, making them suitable for applications requiring rapid movement and flexibility.

Pneumatic actuators come in different configurations, including single-acting and double-acting types. Single-acting pneumatic actuators use air pressure to move in one direction and a spring return to return the original position. Double-acting actuators, on the other hand, employ air pressure for movement in both directions. These actuators can provide both rotational and linear motion, allowing for versatility in automated processes.

Air Actuators vs. Electric Actuators

When comparing pneumatic and electric actuators, pneumatic systems, like those made by BMD, have been a trusted choice for centuries, especially in industries like oil and gas. Using pressure with diaphragm and spring topworks, pneumatic actuators don’t need electric current or an air compressor, making them ideal for remote, hazardous environments. Electric actuators, while not requiring gas, need both power and an air compressor, complicating installation and maintenance, especially in isolated areas.

Retrofitting electric actuators onto existing valves introduces a steep learning curve, similar to modern car technology, with potential reliability issues in remote locations. Pneumatic actuators are well-established, easier to maintain, and suited for applications requiring durability. Ball valves and butterfly valves play a key role in controlling fluid flow in both actuator systems, offering versatility in various applications.

Proper mounting of solenoid valves and direct mount solenoid valves is crucial for system stability. Correct installation ensures reliable operation and prevents malfunctions, particularly in demanding environments. Choosing the right actuator depends on the specific application, with pneumatic favored for remote, rugged environments, and electric actuators offering precise control where needed.

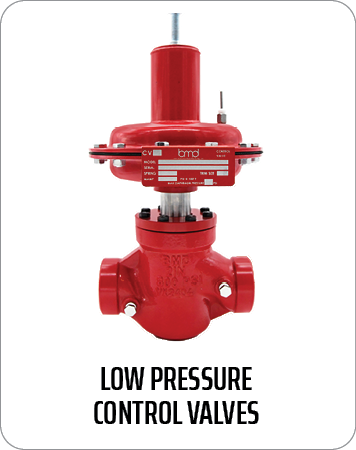

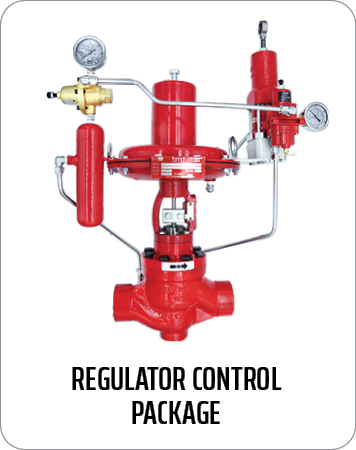

Control Systems and Speed Controllers

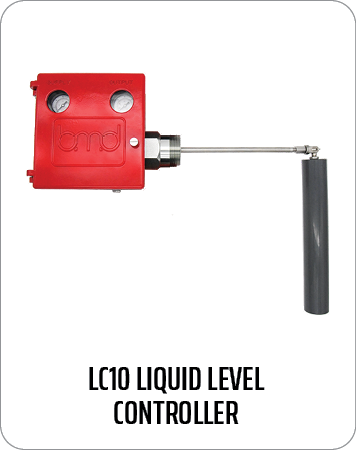

Pneumatic control systems and speed controllers play a vital role in optimizing actuator performance. Control systems use compressed air to power machinery and regulate the flow and pressure applied to actuators, ensuring precise movement of mechanical parts. Sensors within these systems monitor variables like pressure and temperature, automatically adjusting pumps or motors to maintain optimal conditions.

Speed controllers, also known as flow controls, enhance actuator efficiency by regulating the flow rate in one direction while allowing full flow in the other. This ensures controlled, precise movement in one direction and faster return in the opposite. Integrated pilot check valves and adjustable stems or knobs further allow for fine-tuning of airflow, while built-in indicators provide real-time diagnostics. By using meter-out or meter-in valves, speed controllers can precisely manage exhaust or input air, contributing to smoother, more efficient actuator operations.

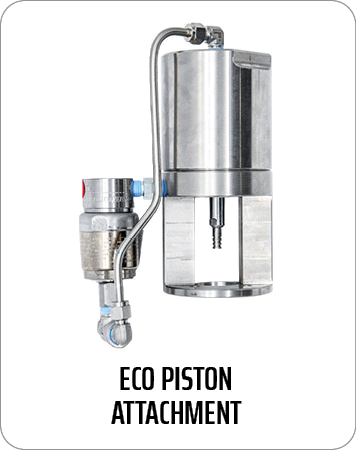

Eco piston – zero emissions actuator

The eco piston is a unique zero-emissions actuator that offers a sustainable alternative to traditional pneumatic systems. Unlike pneumatic systems that require an air compressor, the eco piston operates using gas, which circulates through the system without being exhausted. This closed-loop design eliminates the need for a compressor while maintaining the benefits of pneumatic-like control.

By looping gas back into the system, the eco piston provides reliable operation without the energy consumption or environmental impact of compressed air systems. This innovative technology brings a new level of efficiency and control to the market, combining the best of both pneumatic and electric actuators while helping industries reduce emissions and meet stringent environmental standards.

FAQs

- What distinguishes instrument air from process air?

Instrument air is pressurized air, typically up to 20 psi, used mainly for control purposes such as operating thermostats and pneumatic controls, similar to how low voltage is used in electrical systems to operate relays and contactors. In contrast, process air is utilized directly in industrial processes. - What is the function of an instrument air system?

An instrument air system is designed to ensure a continuous supply of compressed air that meets the necessary quality and pressure standards for operating instruments, controls, and other station utilities. - Why do control valves require instrument air?

Instrument air is essential in plants for multiple functions, primarily for actuating control valves and operating pneumatic instruments. These control valves adjust the flow, pressure, and level of process fluids, while pneumatic instruments are used to monitor and manage these parameters. - What role does a pneumatic actuator play?

Pneumatic actuators are mechanisms that transform the energy of compressed air or gas into mechanical motion. This motion is then used to control one or more final control elements in various applications.