The Basics of Pressure Regulators: What They Are and Why They Matter

The Basics of Pressure Regulators: What They Are and Why They Matter

Oil and gas production systems are characterized by unsteady dynamics due to multiphase, turbulent flows. Sudden gas pressure surges can rupture pipelines and equipment, potentially triggering catastrophic fires or explosions. That’s why precise and reliable pressure control is critically important for oil and gas production systems.

Pressure regulators are self-contained, spring-loaded valves designed to control system pressure, either before or after the regulator. Their self-powered operation makes them an efficient and cost-effective solution for pressure management. Unlike control valves, regulators function without the need for external power sources like air pressure or electric actuators, simplifying installation and reducing operational costs.

For large Oil and operators, who process fluids from hundreds of wells, the cost of pressure control valves is an important consideration. Pressure regulators, due to their simple self-contained design, are a cheaper option to conventional actuated control valves. However, when pressure or flow ranges exceed a regulator’s capacity, control valves or pilot-operated pressure-reducing valves will become necessary.

At Beaumont Manufacturing and Distribution Company (BMD), we excel in industrial pressure regulator and control valve technologies, coupled with a profound understanding of the unique pressure control demands of the oil and gas sector. From our manufacturing facilities in Texas, we deliver a diverse range of pressure-reducing regulators, back pressure regulators, and specialty models. Designed with a focus on durability, safety, and efficiency, BMD pressure regulators are engineered to perform reliably in the most challenging production environments.

What Is a Pressure Regulator?

A pressure regulator is a self-contained pressure control device, designed to maintain the specified pressure level within a system. It can perform either a pressure reducing function or a backpressure control function.

Pressure Reducing Regulators lower upstream pressure to a consistent downstream pressure, regardless of variations in upstream pressure. Conversely, Back Pressure Regulators ensure that upstream pressure remains steady, regardless of changes in downstream pressure.

Regulators operate through three key mechanically interconnected elements. The first is a control element, consisting of a movable disc and a seat which adjusts process fluid flow by varying the flow area in the valve by moving the disc closer or further from the seat. The loading element, often a spring, sets the pressure. The sensing element, typically a diaphragm, balances force and adjusts the discs position from the seat, maintaining consistent system pressure despite condition changes.

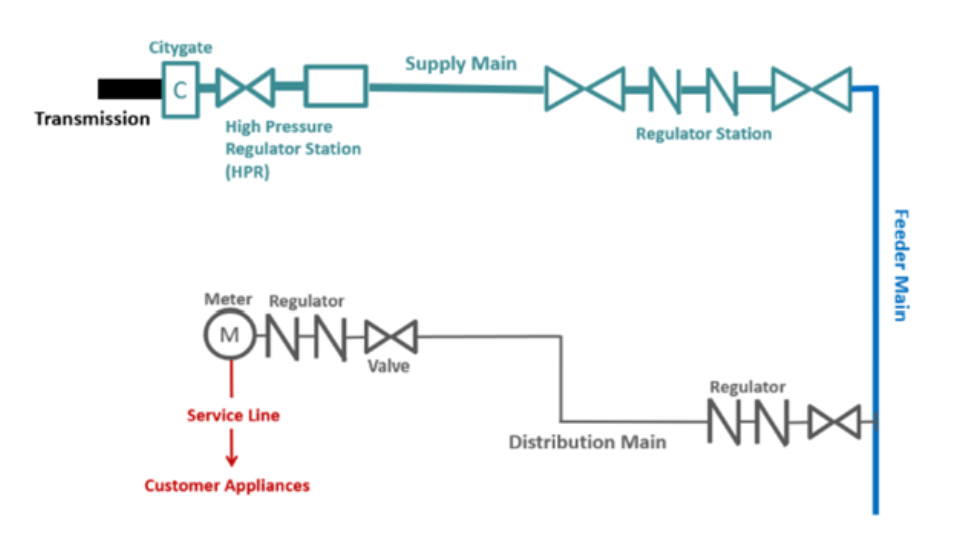

The diagram above illustrates the use of regulators in maintaining the necessary pressure levels within distribution systems. The selection of regulators over conventional control valves is primarily influenced by their lower cost. However, when flow rates or pressure ranges surpass the capabilities of pressure regulators, the use of control valves becomes essential for effective pressure control.

The applications of pressure regulators in the oil and gas industry can be divided into two primary categories:

Pressure Reducing Applications: In these scenarios, downstream systems and devices require a consistent, lower pressure compared to the upstream pressure of the regulator. Examples include:

- Fuel gas supply to burners

- Purge gas supply to vent headers

- Tank blanketing systems for low-pressure tanks in hydrocarbon service

- Instrument air offtakes

- LPG and nitrogen cylinders

Back Pressure Control Applications: Here, the requirement is to maintain a constant pressure in the piping or equipment upstream of the pressure regulator. Examples include:

- Test separators

- Surge drums

- Compressor suction drums

- Heater-treater vessels

Though pressure regulators serve to control pressure within safe limits, their functionality and design differentiate them from control valves or relief valves, as explained below:

Pressure Regulators versus Control Valves: Control valves depend on external sensors, controllers, transducers, and actuators to operate. In contrast, pressure regulators are entirely self-contained, functioning independently by relying on the pressure of the process fluid.

Pressure Regulators versus Relief Valves: Relief valves provide pressure relief in emergency situations when a system’s design pressure is exceeded. On the other hand, pressure regulators maintain a constant, pre-set pressure within the allowable operating range during regular operations.

Why Pressure Regulators Matter in Oil & Gas

Pressure regulators play a vital role in the oil and gas industry, ensuring smooth, efficient and reliable operations.

Optimal Equipment Performance: Essential equipment, including compressors and separators, require precise pressure control for effective functioning. In remote and smaller applications lacking computerized control systems, pressure regulators ensure consistent pressure management regardless of upstream or downstream fluctuations.

Downtime and Efficiency: Overpressure incidents can cause costly production deferment or system trips leading to production loss. Regulators stabilize pressure to minimize unnecessary shutdowns and system restarts, enhancing operational efficiency and reducing maintenance costs.

Compliance and Sustainability: By maintaining proper pressure levels, pressure regulators prevent leaks and emissions, protecting the environment while ensuring adherence to regulations. Their reliability supports sustainable operations and shields companies from legal issues or fines.

Pressure Regulator Products Manufactured by BMD

BMD excels in the design and manufacture of pressure regulators, offering both direct-acting and pilot-operated regulators.

Direct-acting regulators use a simple design comprising a single loading spring, diaphragm, and disc-seat assembly. These components perform the functions of loading, sensing, and flow control. Due to their robust and simple construction, direct-acting regulators offer quick responsiveness and exceptional reliability.

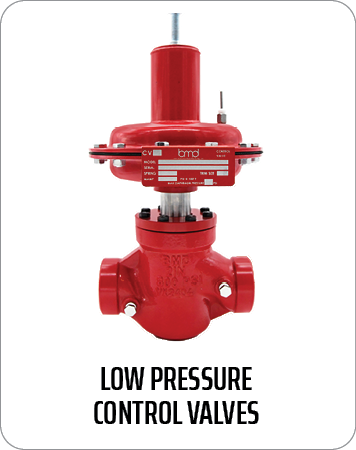

BMD’s product range includes the following direct-acting pressure reducing regulators:

RG10, RG20, and RG20H: These pressure-reducing regulators are designed for heavy-duty oil and gas applications.

The RG10 accommodates a maximum inlet pressure of 1500 psi and delivers an outlet pressure range of 27–500 psi. These models are available in body sizes of 1” and 2”. The materials of construction for RG10 include WCB Steel for the body, brass/stainless options for trim, Buna, Viton® and Nylon for the disk, Viton®/Neoprene for the diaphragm. The RG20 has a max inlet of 2000 psi with spring ranges from 5 to 500 psi. Material options for the RG 20 series include WCB Steel for the body, Aluminium /Stainless steel options for trim, Buna, Viton® and Nylon for the disk and Buna/ Viton® for the diaphragm.

RG30 and RG40: These pressure-reducing regulators are suitable for instrument air and pneumatic systems. The RG30 is ideal for regulating flow in instrument air applications, such as controlling valves and positioners. Meanwhile, the RG40 is designed for chemical injection pumps, valve actuators, and controllers. Both models feature a 1/4” NPT connection compatible with tubing. While the RG30 employs a traditional single inlet and outlet configuration,the RG30 has 2 outlets. The RG40 is equipped with one inlet and three outlets, enabling it to manage multiple loads simultaneously. The RG30 supports a maximum inlet pressure of 250 psi, whereas the RG40 boasts an impressive rating of 5000 psi. The RG30 comes in die-cast Aluminium for the body and housing. The RG40 is available with Brass or 316SS options for the body and housing, Stainless steel/ 316SS for the trim, Nylon and PTFE for the disk and Stainless Steel or Monel 400 for the diaphragm.

Pilot-operated regulators are more complex than direct-acting regulators but offer higher capacity and precise control. These regulators utilize a smaller direct-acting pilot to sense process pressure and operate the main regulator. Unlike direct-acting designs, the diaphragm of the main regulator does not directly respond to process pressure. Instead, it moves based on the pressure signal from the pilot. This configuration is particularly advantageous for high-flow capacity and precision control applications in the oil and gas industry.

One example from our portfolio is the BMD RG50, a versatile and accurate pilot operated pressure-reducing regulator. It is used in a broad range of applications including natural gas distribution systems, boilers, furnaces, and more. The RG50 delivers exceptional accuracy, eliminates atmospheric bleed, and ensures a tight shutoff due to its heavy mainspring. Designed for high-capacity pressure control and superior low-pressure regulation, it combines efficiency with easy maintenance. Ideal for applications demanding both high flow and precision, the RG50 is a reliable solution for pressure reduction.

BMD offers three pilot options with varying spring ranges: the RG50H supports a range of 10–65 psi, the RG50HP operates within 35–100 psi, and the RG50LD features multiple springs covering a range from 2 inches water column to 20 psi. For larger line sizes and flow rates BMD manufactures the following models for pressure-reducing and back-pressure control applications.

PR50: The PR50 is a self-contained, non-venting, pilot-operated pressure-reducing regulator. It is designed for applications such as compressor suction pressure control and gas supply or distribution pressure control.

BP50: The BP50 is a versatile, emission-free, pilot-operated back-pressure regulator. It is specifically designed for vent line applications and is commonly utilized in separators, heater treaters, compressors, and gathering systems.

Both PR50 and BP50 models are available in various body sizes, pressure ratings and end connections as follows:

- Threaded End Connection: This variant has a pressure rating of 300 psi and is offered in 2” and 3” valve body sizes.

- Flanged End Connection: This model comes with a pressure rating of 250 psi and is available in 2”, 3”, 4”, and 6” valve body sizes.

Both PR50 and BP50 models come with Body, Bonnet, and Hub made from ductile iron, and stainless steel internals.

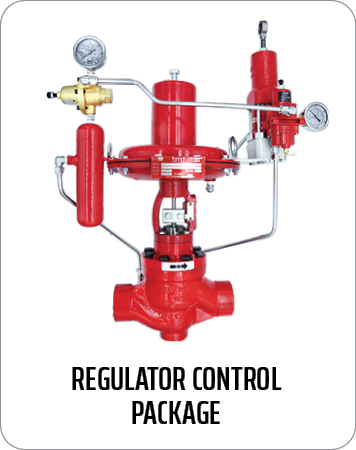

Regulator packages: BMD offers fully assembled and factory-tested regulator packages for both pressure reduction and back-pressure control. These packages feature BMD’s PC88, PC48, or PC28 pilot for pressure sensing, two RG-type direct-acting instrument air filter regulators, a drip pot with drain, and interconnecting tubing.

Pilots are available for low, medium and high-pressure settings ranging from 0.5 ounces to 1500 psi. Material options include Buna and Viton® for seals. When combined with a BMD control valve (ordered separately), the package is field-ready for complete pressure control applications.

BMD’s versatile and extensive range of pressure regulators is compatible with the diverse requirements of upstream, midstream, and downstream sectors. Engineered for durability, their robust construction withstands the rigorous demands of the upstream sector, while the wide selection of models provides precision, corrosion resistance, and emission-free performance essential for midstream and downstream hydrocarbon processes as well as chemical industries.

What Sets BMD Pressure Regulators Apart

BMD Pressure Regulators deliver unmatched performance and reliability. Proudly engineered and manufactured in Texas, they are built to endure the most extreme field conditions. With extensive customization options, they cater to specialized applications across industries. Backed by rigorous quality assurance and certifications, BMD regulators offer peace of mind in every operation. Count on our reliable delivery and expert technical support to ensure your systems run smoothly. When you choose a BMD product, you’re investing in unparalleled precision, enduring durability, and proven excellence.

Choosing the Right BMD Pressure Regulator for Your Application

Pressure regulators selection requires evaluating several factors as follows:

Pressure Range: Identify both the operating and maximum allowable pressure for the system. A regulator should maintain pressure levels within this range, ensuring efficiency and safety.

Media Compatibility: Choose materials compatible with the media (air, gas, chemicals) to prevent corrosion and contamination.

Flow Requirements: Ensure the regulator is sized to handle the required flow rate. High-flow systems need regulators with larger valve openings and precise control.

Installation Environment: Consider factors like temperature, humidity, and exposure to chemicals. Use durable regulators for harsh or outdoor environments.

Common use cases for BMD pressure regulators include:

- Oil gas production: Pressure control in separators, Surge drums, Compressor suction drums and Heater-treater vessels.

- Natural Gas Distribution: Managing pressure in mainlines and fuel lines.

- Reactors and Storage Tanks: For precise pressure control and blanketing service.

- Instrument air and Pneumatic Systems: To regulate air or gas supply to control valve, positioners, chemical injection pumps.

Maintenance and Support for BMD Regulators

BMD’s pressure regulators offer durable construction, easy maintenance, and reliable performance. Replacement parts are always available, thanks to robust production capabilities.

Supported by detailed documentation and exceptional customer service from skilled technicians, field representatives, and engineers, BMD delivers expertise nationwide.

Conclusion

Pressure regulators play a critical role in maintaining stable pressure control, across a wide range of industries. BMD’s pressure regulators ensure reliable pressure control in demanding industrial applications, safeguarding equipment and piping from overpressure risks.

Designed for reliability and safety, our innovative, eco-friendly valve solutions deliver exceptional performance. With a diverse range of high-quality options, BMD empowers industries to tackle the toughest challenges with confidence and efficiency.

Looking for the perfect pressure control valve? Our team is here to assist you. Let BMD empower your operations with top-tier pressure regulators that set new benchmarks in safety and reliability. Don’t settle for less—reach out to BMD for a quote, spec sheet, or expert consultation now!