A Comprehensive Guide to Selecting the Right Relief Valve for Your Oil and Gas Needs

Oil and gas production involves managing large volumes of hydrocarbon fluids, often under high temperatures and pressures. Due to this, production systems—composed of wells, wellheads, pipelines, vessels, pumps, and compressors—must be equipped with robust protection mechanisms to prevent failures caused by overpressure.

Among these, relief valves are the most vital components for overpressure protection within a pressurized system. Their importance is such that they are commonly referred to in the industry as “Ultimate Safeguards.”

Relief valves safeguard oil and gas production systems by preventing ruptures caused by excessive pressure. They help shield personnel, the environment, and infrastructure from catastrophic outcomes that can be caused by uncontrolled hydrocarbon release. They contribute to operational efficiency by ensuring that pressure excursions are safely handled while preserving the integrity of production systems.

Beaumont Manufacturing and Distribution Company (BMD) is a trusted relief valve supplier to the oil and gas industry, with a range of safety relief valves that are well-suited for overpressure protection of production equipment.

This guide will help you to select the correct relief valves for your oil and gas applications. It covers the working principles, key selection criteria, regulatory aspects, proper installation, and maintenance practices.

Understanding Relief Valves in Oil and Gas Applications

A relief valve is a pressure control device that opens to relieve excess pressure and recloses once conditions normalize. A conventional relief valve has an inlet nozzle, a movable disc, and a spring that sets the pressure threshold. By balancing forces, fluid pressure exceeding the spring’s set limit opens the valve, safely releasing excess fluid. When pressure falls, the spring reseats the disc, closing the valve. This mechanism prevents overpressure and ensures safe system operation.

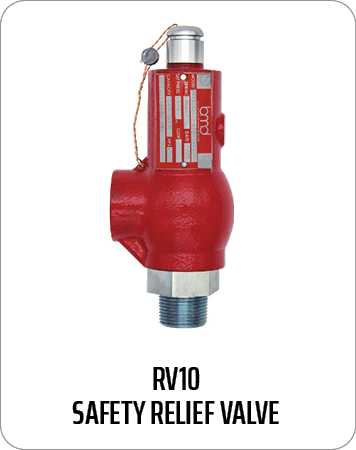

BMD’s RV10 relief valves are precision-built for overpressure protection of production equipment and designed for longevity, efficiency, and reliability in the field. RV10 relief valves are manufactured in accordance with the ASME BPVC, and capacity tested and certified by the National Board.

Relief valves in oil and gas operations prevent overpressure in equipment like separators, compressors, and pipelines. These situations could arise, for example, due to blockages, surges, thermal expansion, or control failures. By opening at preset pressure levels, relief valves safely release excess fluid into a relief header system, protecting equipment from rupture and ensuring operational safety.

Key Factors to Consider When Selecting a Relief Valve

Choosing the right relief valve involves evaluating several key factors to match the valve with system requirements effectively. Some key factors are:

Operating Pressure and Set Pressure: To avoid leakage due to simmering action when the maximum operating pressure approaches the relief valve set pressure, sufficient margin must be provided between the two. For most applications the operating pressure should be no more than 90% of the set pressure. If vibration is present or pressure surges are expected then it should be even lower.

Flow Capacity (Sizing Considerations): Relief valves must be sized for the worst-case relieving scenario (governing case). When sizing a relief valve the required capacity, set pressure, relieving temperature, and fluid properties should be specified in order to properly select the correct size valve. In some cases multiple valves may be used in parallel. Flow capacity calculations are performed per API and ASME codes.

Type of Fluid/Gas Being Processed: The physical and chemical properties of the fluid being handled impact the size of relief valve needed, as well as choice of materials. All operating and relieving scenarios must be considered while evaluating the fluid properties. For example, crude oil may be light or viscous, there may be fouling asphaltenes or waxy substances. Natural gas may contain corrosive acid components. Gas with free water may form hydrates.

Temperature and Environmental Conditions: Relief valves must retain their integrity at conditions to which they are constantly exposed as well as at relieving conditions. High temperatures need heat-resistant components, while cryogenic systems demand materials suited to extreme cold. Environmental factors such as ambient temperature, humidity, precipitation, desert conditions, and offshore service, will affect the choice of materials.

Material Compatibility: It must be ensured that the materials used in the relief valve are compatible with the process fluid at all operating and relieving conditions. For example, relieving scenarios may be at high temperatures and pressures whereas operating conditions may be mild. Corrosion resistance is essential. BMD relief valves are manufactured using different materials as shown in Figure 1.

BMD Relief Valves and Their Applications

Overpressure risks in the oil and gas industry encompass a wide range of operating conditions. BMD’s RV10 series of spring-loaded relief valves span a set-pressure range of 15-3000 psi and temperature range of -50 oF-400 o F. Available in different models to suit varying requirements, RV10 safety relief valves are an ideal choice for overpressure protection of compressors, scrubbers, separators, pipelines and other systems where overpressure protection may be required. BMD’s RV10 Relief Valves incorporate a non-rising stem design that gives the disk full guidance, while opening and closing.

This is coupled with a soft seat design that ensures long lasting set pressure repeatability and bubble tight shut-off. The shorter stem makes the valve compact and ideal for tight spaces. The RV10 is ASME-certified for gas and liquid service and is available in NPT and flanged connections. The flanged relief valve sizes meet API 526 dimensions. The RV10 is manufactured in accordance with the ASME Boiler and Pressure Vessel Code, capacity tested and certified by the National Board, and meets the requirements of Sec on VIII, Division 1 of the ASME Code.

Regulatory Compliance and Industry Standards for Relief Valves

Relief valve design and operation are subject to rigorous regulations established by various organizations. For oil and gas installations within the USA, the most important national standards are as follows:

API Standard 520, Part 1 Sizing, Selection, and Installation of Pressure-relieving Devices Part I—Sizing and Selection.

API Standard 520 Part II, Sizing, Selection, and Installation of Pressure-relieving Devices Part II—Installation.

API Standard 521, Pressure-relieving and Depressuring Systems.

API Standard 526, Flanged Steel Pressure-relief Valves.

API Standard 527: Pressure Relief Valve Seat Tightness.

ASME Boiler and Pressure Vessel Code (BPVC).

Regular inspections, testing, and documentation are critical for demonstrating compliance during audits.

Best Practices for Installation and Maintenance

Relief valves should always be installed and maintained according to manufacturer guidelines and industry standards. Position the valve vertically. The inlet piping should be short and direct, without pockets. Ensure nameplate details are visible. Outlet piping should be free, draining away from the valve to prevent liquid accumulation. Provide proper supports for valve and piping considering reaction forces.

Relief valves are not an end user serviceable device. They must be worked on by a certified VR shop. They should be tested annually at minimum to verify set pressure and that the valve is free to operate.

Choosing the Right Safety Relief Valve Manufacturer

Selecting the right safety relief valve manufacturer is crucial for system performance and safety.

What to Look for in a Reliable Relief Valve Supplier

Quality Certifications and Industry Reputation

Choose a supplier who values meeting the highest industry standard, and with proven expertise in industry-specific valves. Ensure they meet quality standards and certification like ISO-9001 and ASME certification, showcasing compliance and a commitment to quality management and excellence. A strong reputation backed by customer reviews and industry recognition is essential.

Technical Support Availability

Since relief valves are critical to the safety of oil and gas production facilities, assurance of prompt and reliable technical support from suppliers is very important.

Conclusion

Selecting the right relief valve involves assessing key factors like operating pressure, material compatibility and selecting a manufacturer who is reputable and values the highest quality standards. Choosing a high quality relief valve for your oil and gas system is vital to the integrity of your system, and the safety and protection of your environment and personnel. Properly specified, installed, and maintained relief valves ensure safety, operational integrity, and compliance with stringent industry standards. Protect your people, your environment, and your infrastructure with BMD’s trusted safety relief valves. Contact BMD today for expert guidance and top-tier relief valve solutions for your oil and gas system.